CANADIAN BEEF GRADING AGENCY

Beef Grading

GRADED PRODUCT VS UNGRADED PRODUCT

Beef is graded in two ways: quality grades for tenderness, juiciness and flavor; and yield grades are a prediction of the percentage of boneless retail cuts from the four primal cuts (round, loin, rib and chuck). A beef carcass is graded by a certified and designated grader only after it bears a CFIA meat inspection stamp.

From a consumer standpoint, what do these quality beef grades mean? Beef grades measures several characteristics that reflect the overall quality of the meat.

Grading attempts to ensure that consumers have an improved product through greater consistency and predictability in the eating quality of specific grades of beef. In Canada, our top beef grade is Canada Prime, followed by Canada AAA, Canada AA, and Canada A.

Grading is not mandatory, but the grade is the commonly accepted criteria used to establish market value. Grading is intended to place carcasses into uniform groups of similar quality, yield and commercial value in order to facilitate marketing and production decisions.

The Canadian Beef Grading Agency (CBGA) is a private not-for-profit corporation accredited by the Canadian Food Inspection Agency to deliver grading services for beef carcasses in Canada. The beef grade standards or “Requirements” for what constitutes a grade are managed by the industry Livestock Grade Requirements Standing Committee, as overseen by the Board of Directors of the CBGA. These Requirements are empowered through incorporation by reference in the Safe Food for Canadians Regulations, as established by the Canadian Food Inspection Agency.

As you can see, there is a lot involved when it comes to grading beef.

So, what is Ungraded Beef?

Essentially, you’re getting a product that is inspected by CFIA and meets the SFCR so is safe to eat, and is edible, but you don’t necessarily know what you’re getting from a quality perspective.

There have been recent media reports and posts commenting on the import of Ungraded Mexican beef into Canada.

All meat products (Graded and Ungraded) sold in Canada must first be inspected by the Canadian Food Inspection Agency (CFIA). Canadian food safety has high standards recognized internationally. Any meat product imported from one of the approved countries by CFIA has been deemed equivalent to meet Canadian food safety standards.

Therefore, the term “ungraded” does not mean “uninspected” or “unsafe”.

It is not permitted to use a Canada TM grade name on a product for which the regulations do not prescribe a grade standard. As a general rule, a Canada TM grade name cannot be applied in a foreign facility, nor can a foreign grade name be applied in Canada. It is also not permitted to apply or use anything that resembles a grade name, or that is likely to be mistaken for one.

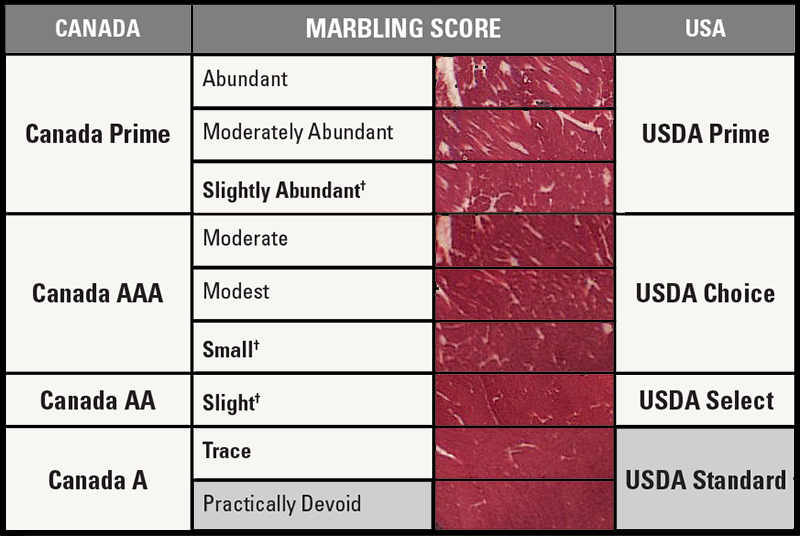

When Canadian Graded beef products are imported to the United States, they are not permitted to be labeled with USDA TM Grade Names. They are recognized by their Canada TM Grade Names (Canada Prime, Canada AAA, Canada AA and Canada A), and marketed as such there, unless it is an UNGRADED Product, and then those products would bear that notation. The exception is Canada AAA, which is eligible to be labelled as CANADA CHOICE when exported, as the quality is the recognized equivalent with USDA CHOICE.

Grading systems of other countries for beef

Canada is presently recognizing the grading system of the following countries only: Argentina, Australia, New Zealand, United States and Uruguay. For more information you can visit the CFIA website at :

THE IMPORTANCE OF THE GRADER AND GRADE CONSISTENCY

A thorough understanding of the general characteristics, dressing and chilling practices and presentation as they pertain to the harvest of a beef carcass is critical for consistent assessment of the grade Requirements.

Every carcass bears a commercial value based on its quality and yield as assessed at a specific time and location. It is imperative that each carcass assessment be accurate and consistent within the Requirements.

TO CORRECTLY ASSESS A CARCASS, THE FOLLOWING ARE NECESSARY:

- Understand all the factors and characteristics that influence carcass quality and yield.

- Understand and readily identify the factors which influence different grade outcomes as defined in the Requirements. Apply the assessment of required factors using logical, objective and consistent judgement.

- Monitor harvest floor activities for carcass dressing and trim to ensure fair producer weight compensation.

- Monitor the scales and hot carcass weight accuracy for subsequent producer payment.

- Monitor the sorting and segregation of carcasses to ensure the integrity of the grade labels on boxed product.

HOW BEEF IS GRADED

A carcass may only be graded after it has been inspected and approved for health and safety standards. A designated grader assesses a carcass based on several criteria which are scientifically proven to influence either carcass quality and/or yield. When available, approved objective technologies to assess required factors in a beef carcass may be utilized as a tool to facilitate consistent grading.

CAPTURING THE GRADE

In the age of technology, it is no longer mandatory to physically stamp a carcass with the grade and yield symbol. Data capture systems exist that ensure grade integrity throughout the manufacturing process and for market settlement back to the producer. As long as these systems are documented and monitored by the grader to ensure grade name integrity, stamping is optional. However, when grade stamping is requested it is done as clearly and neatly as possible so that the grade name is easily recognized.

GRADE LABELING

When beef is fabricated into wholesale and/or retail cuts, the grade label on the box must correspond to the grade assessed for the carcass verified either through the stamp or data capture system. The designation “or Higher” is allowed if a box contains assorted product that includes more than one of Canada A grades (Canada A, Canada AA, Canada AAA and Canada Prime). The label on a box of mixed A grades must reflect the lowest marbled grade contained in the box.

INSTRUMENT AUGMENTED GRADING

One development in the Canadian Grading System was implementation of the computer vision grading system e+v Technology (VIA technology: VBS 2000, E+V GmbH, Germany). Computer vision grading technology enables multiple measurements of yield and quality grade parameters to be made more quickly than would be possible using manual approaches.

The final grade is always overseen/approved by a CBGA certified and CFIA designated grader, who are able to, if necessary, overrule the camera’s grading scores should they not be accurate.

GRADES ON IMPORTED BEEF

Beef which is imported into Canada must be inspected but does not have to be graded. The Safe Food for Canadians Regulations require that containers of imported beef must bear the grade name from the country of origin or be identified as ungraded beef.

GRADE EQUIVALENCY WITH THE UNITED STATES

The North American market for beef is integrated. Using the same marbling standards for USDA Prime, Choice and Select as those used for Canada Prime, Canada AAA and Canada AA, respectively, and using the same yield classes provides marketing transparency across the border.

REQUIRED GRADING FACTORS

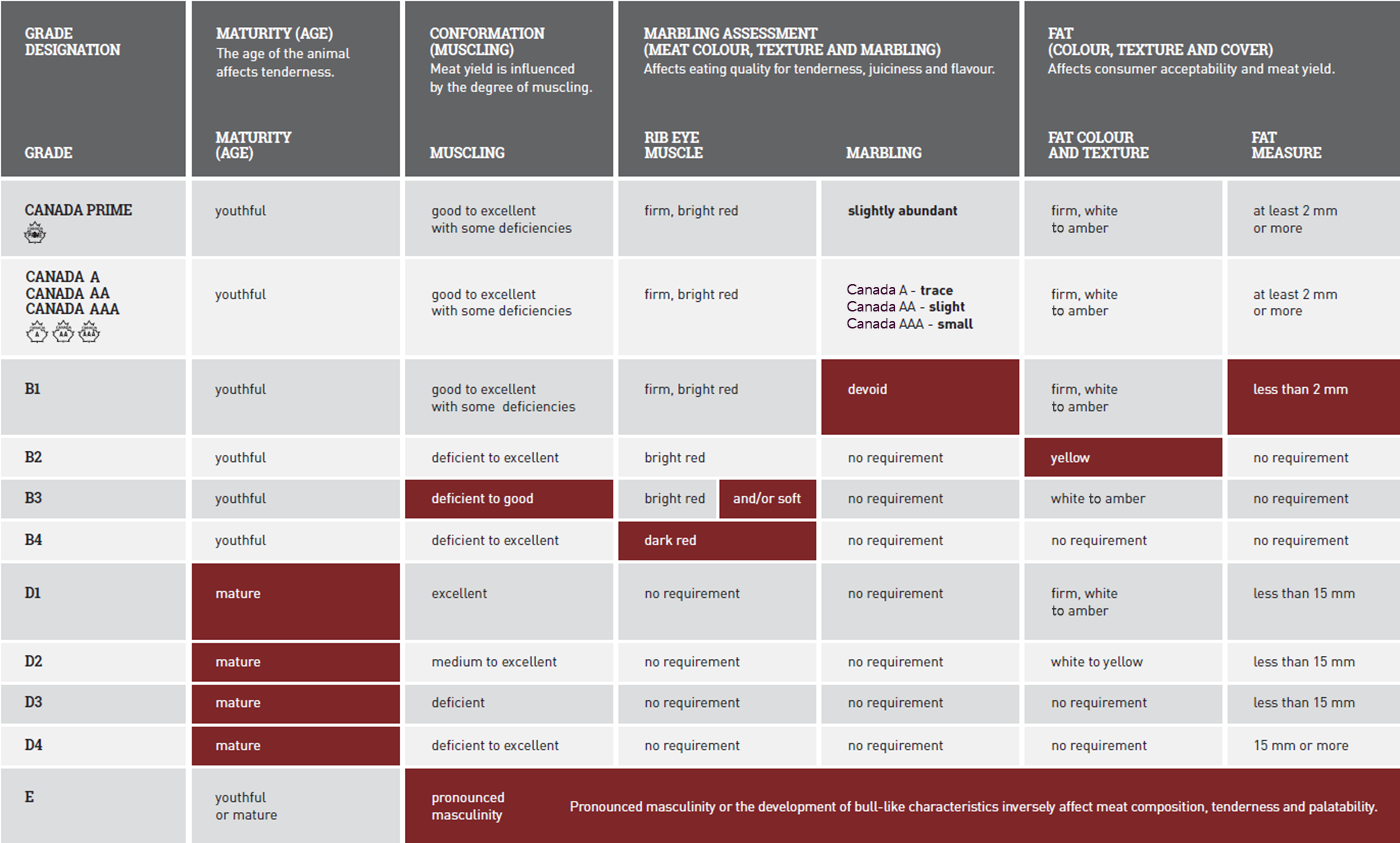

The required factors used in grade assessment (shown in chart) are directly related to the tenderness, juiciness, flavour, consumer acceptability, shelf life and cut yield. The areas highlighted in red represent the distinguishing criteria which eliminates the carcass from the quality grades A or higher.

MARBLING

The assessment of marbling is based on the amount, size and distribution of fat particles or deposits in the rib eye. Canadian marbling standards are grouped into categories: Canada A, Canada AA, Canada AAA and Canada Prime. These standards are based on USDA marbling standards (identified in bold): Trace, Slight, Small and Slightly Abundant. USDA marbling standards also identify the following grades which are often used for branded programs: Small 50, Modest, Moderate, Moderately Abundant, Abundant and Very Abundant.

† The above illustrations are reduced reproductions of the official USDA Marbling photographs prepared for the U.S. Department of Agriculture by and available from the National Cattlemen’s Beef Association.

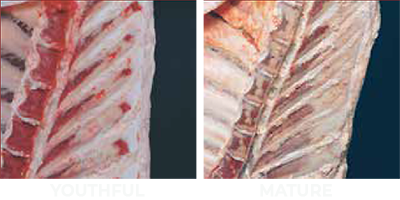

MATURITY (AGE)

The assessment of the degree of ossification (bone hardening) determines

Youthful or Mature. Ossification increases as the animal ages. Youthful

carcasses are more tender than mature.

MEAT COLOR

Dark red (the determining factor in a B4 Grade) is established by comparison with a standardized CBGA colour chit identified as Borderline.

When the rib eye is compared to the colour chit and is equal to or darker, the carcass is assessed as a dark cutter. Dark cutters have a reduced shelf life.

FAT ATTRIBUTES

Consumers consider meat and fat color as important indicators of beef quality. To qualify as Canada A, Canada AA, Canada AAA or Canada Prime, fat cannot have a yellow tinge and must also be assessed as firm and consistent. Optimal fat cover enables the carcass to cool in a way which maximizes eating quality.

BEEF CARCASS YIELD

RETAIL CUT YIELD DEFINITION

When a carcass qualifies for Canada Prime or any of the Canada A grades, a prediction of retail cut yield percentage, an estimation of closely trimmed (0.5 inch or 13 mm fat or less) boneless retail cuts from the four primal cuts (round, loin, rib and chuck) is made.

PREDICTING RETAIL CUT YIELD

The method that is used to estimate retail cut yield was developed in the United States and adapted by Agriculture and Agri-food Canada, Lacombe Research and Development Centre, and implemented in January 2019. Yield class reported back to the producer will facilitate informed management decisions, providing the opportunity to identify feed efficiencies and desirable genetics. Yield class can facilitate packer segregation of carcasses for higher processing efficiencies.

THE YIELD CLASSES

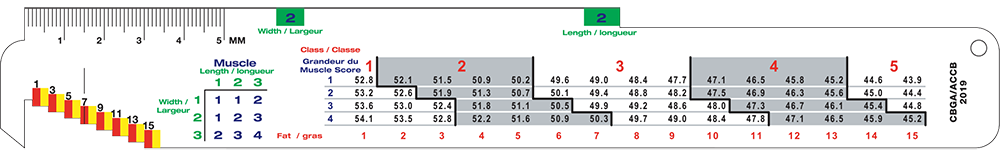

The yield class reported by the grader is a prediction of the percentage of retail cut yield in a carcass.

| Yield Class | Estimated Retail Cut Yield(%) |

|---|---|

| Canada 1 | 52.4 or more |

| Canada 2 | 50.2 to 52.2 |

| Canada 3 | 47.7 to 50.1 |

| Canada 4 | 45.2 to 47.5 |

| Canada 5 | 45.0 or less |

THE YIELD EQUATION

Retail Cut Yield % = 53.13 + (0.44 x muscle score) – (0.32 x fat thickness, mm)

THE YIELD RULER*

*not actual size

YIELD MEASUREMENT

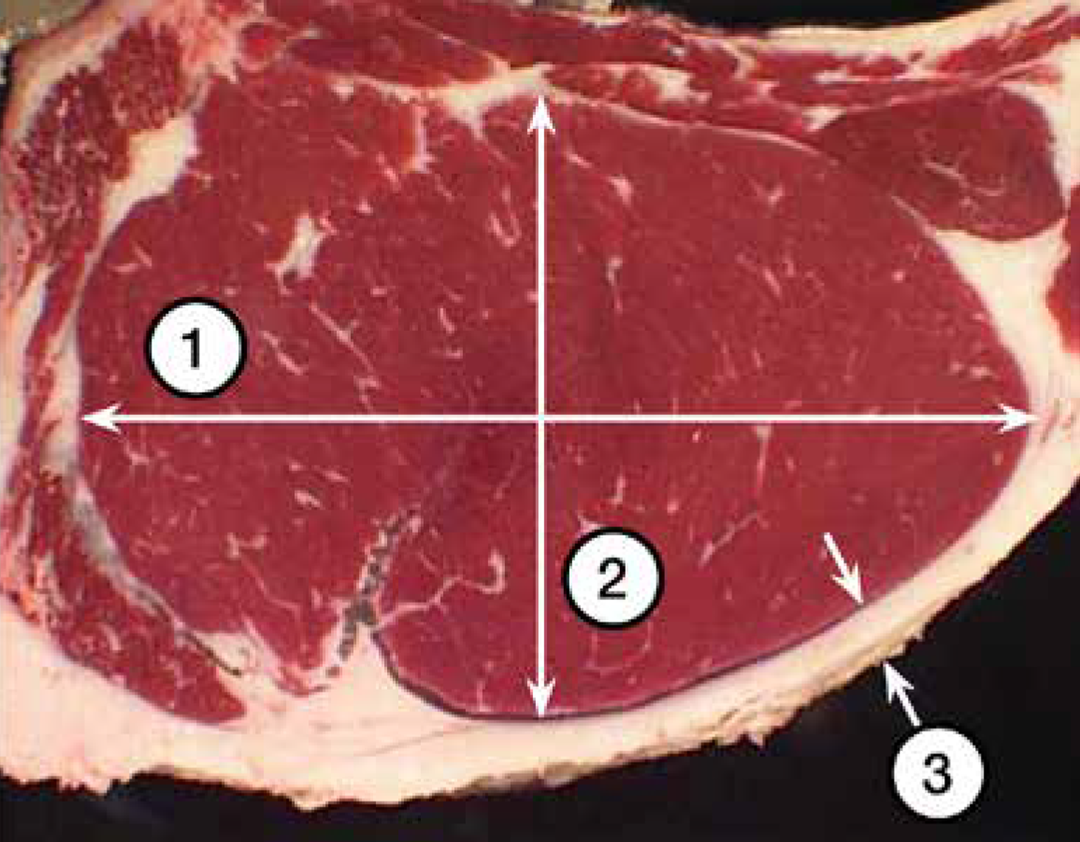

To determine whether the Yield Class is 1, 2, 3, 4, or 5, the ruler is applied to the surface that is exposed when the carcass is ribbed between the 12th and 13th ribs.

- LENGTH

— maximum length of the rib-eye - WIDTH

— maximum width of the rib-eye

— is perpendicular to the longitudinal axis

— within the second and third quarter of the rib-eye - FAT CLASS

— fat assessed perpendicular to the outside surface

— measured at a point three quarters of the length

of the rib eye from the split edge.

Training Video For Consistent Application of Yield Assessment

INSTRUMENT AUGMENTED GRADING

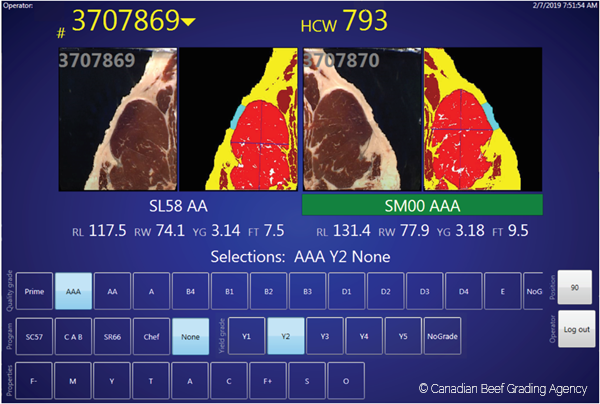

One development in the Canadian Grading System was implementation of the computer vision grading system e+v Technology (VIA technology: VBS 2000, E+V GmbH, Germany). The system’s original LED cameras have since been updated with digital (GigE) cameras. Computer vision grading technology enables multiple measurements of yield and quality grade parameters to be made more quickly than would be possible using manual approaches. Further, the digital format of the carcass data enables the information to be stored in industry databases such as BIXS.

It marked the first major advancement in the Canadian system since the Computer Vision System (CVS) camera was introduced in 1999. The e+v technology is approved for use as a grading aid by the Canadian Food Inspection Agency and enables improved grading accuracy under current grading regulations. The final grade is always overseen/approved by a CBGA certified and CFIA designated grader, who are able to, if necessary, override the camera’s grading scores should they not be accurate.

In Canada, the e+v grading instrument is a stationary machine that photographs and analyses the rib eye area between the 12th and 13th ribs of both sides of each carcass as it passes by on a moving rail. At present, the computer grading camera measures grade fat, rib eye width, rib eye length, and calculates a retail cut yield, providing a yield class and a marbling score which equates to a quality grade. Once approved, there are regular audits and oversight of the technology to insure its accuracies and compliance as set forth in the Packer-Agency Contract, Schedule B-I “Requirements for Instrument Augmented Grading”.

Currently, four establishments in Canada have a moving rail – JBS (formally XL Beef) in Brooks, Cargill High River, Cargill Guelph, and Harmony Beef in Balzac, all have installed the instrument but the JBS facility was the first, and continues to be the only to use it to augment beef carcass grading. While the other facilities have utilized the technology for “in-house” purposes over the past years, there are currently others now at various stages of the adoption of computer vision systems as an aide in grading at their establishments.

The technology is objective and assesses marbling under the same light and at the same distance from the rib eye based on minute calculations of red and white pixels within the traced muscle. The information captured can be stored, shared and further analyzed.

The above image is showing a grading screen from the e+v system.